- Home /

- Watermakers /

- Aqua Matic

You have no obligation to purchase the product once you know the price. You can simply remove the item from your cart.

You have no obligation to purchase the product once you know the price. You can simply remove the item from your cart.

- Features

- Specifications

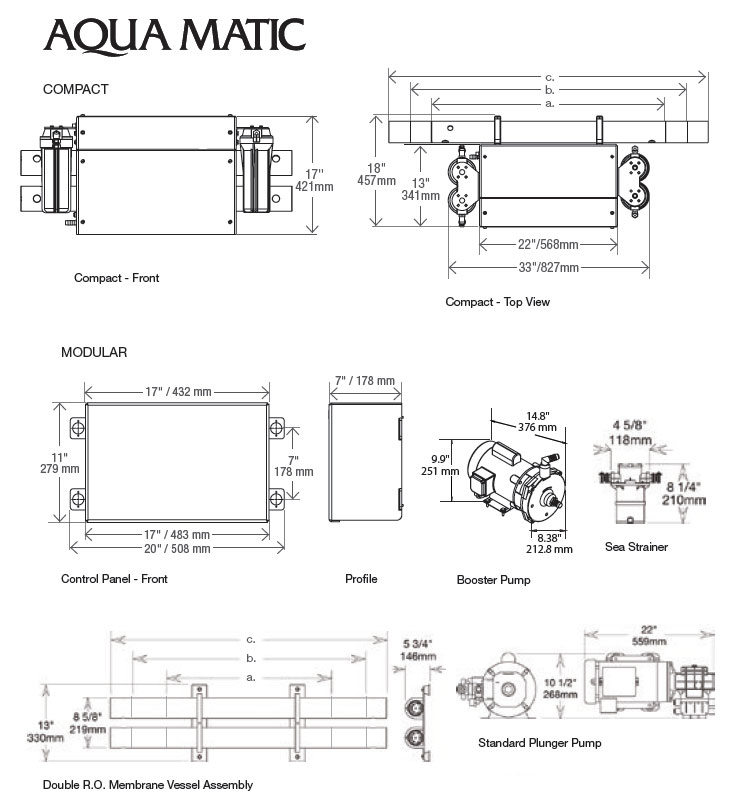

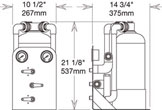

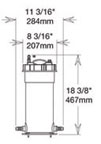

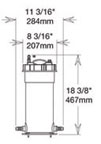

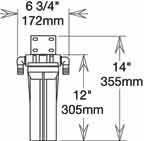

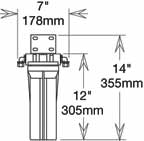

- Dimensions

- Accessories

- Consumables

- Contact

Features

AQUA MATIC – KEY FEATURES

The revolutionary Aqua Matic is engineered to be easier to use and more reliable than conventional watermakers. Featuring the latest technology, the Aqua Matic is able to regulate and monitor functions without the need of an operator. with one touch, the Aqua Matic will start and finish water production automatically, allowing boaters more time to relax and enjoy their cruise.

One touch operation and full color touch screen.

The new Aqua Matic is NMEA 2000 compliant, giving you the power to monitor and communicate with your system through any NMEA compatible display.

One touch operation and full color touch screen

Equipped with an automated pressure regulating system and Fresh Water Flush, the Aqua Matic can fully operate and perform self maintenance functions without the need of an operator.

Oil free high pressure pump (optional)

The Aqua Matic's Super Duplex Radial Axial Pump is water lubricated and requires no oil changes. It has a maintenance schedule every 8,000 hours, saving you time and money.

AUTOMATED FUNCTIONS

- One-touch automation eliminates the need for an operator’s attention.

- Automatic pressure regulating system – allows the watermaker to balance pressure levels automatically based on any water condition.

- Weekly automatic fresh water flush timing and sequential starting of electric motors with manual override.

- Automatic shut down, either time duration or product quantity.

METERS / MONITORS

- Hour Meter for keeping accurate ship’s logs & schedule preventative maintenance.

- New solid state electronic flow meters for visual monitoring of the product water and feed water flow used to calculate production rates of the system.

- Digital and bar graph Salinity Meter shows actual product water quality, an essential tool for product water monitoring.

PUMPS

- Exclusive high efficiency booster pump for extended pre-filter life.

- Uses a high pressure plunger pump that has a typical maintenance schedule every 2,000 hours.

- Available as an option: Patented High Pressure Quintiplex Radial Axial Plunger Pump is water lubricated, does not require oil changes and operates 8,000 hours between required maintenance.

- State-of-the-art high pressure pump is manufactured with a highly corrosion and erosion resistant Duplex material which provides protection far beyond 316 stainless steel.

- Quiet high pressure pump runs smooth and is free of pulsations.

ACCESSORIES

- Full color remote control touch pad available

- Optional Soft Motor Starter is available for single phase AC powered systems that reduces start up power by 60%.

- Clear viewable Sea Strainer with a cleanable Monel Mesh Screen filter for ultimate corrosion resistance and large particulate removal.

- Charcoal Filter Assembly, Commercial Prefilter, Oil Water Separator, pH Neutralizer, and Automatic Fresh Water Flush are included when requested at the time of order.

NMEA 2000 COMPATIBILITY

- Optional NMEA 2000 compliace interface

- View and monitor system controls through any NMEA compatible display*. You can even start up and shut down your system from your remote display.

- Optional NMEA remote control display available

FULL COLOR TOUCHSCREEN INTERFACE

- Computer interface ready

- Simple-to-use touch screen displays pictorial images of all operating conditions.

- Digital and bar graph readout of all system conditions in U.S. Standard or Metric.

- Ability to display in multiple languages

MATERIALS

- Dedicated heavy duty Magnetic Latching Relays for each motor integrated in the system.

- 316 Stainless Steel Pressure Transducers for accurate measurement of system functions.

- New High rejection / high yield membrane element that produces higher quality product water in a smaller space.

- Fiberglass Reinforced High Pressure Membrane Vessel is stronger and eliminates corrosion.

SAFETY

- A failsafe Product Water Diversion Valve

- Unique Low Voltage Control Circuitry, shielded terminals, and covered high voltage components for end-user safety.

SERVICE AND MAINTENANCE

- The Aqua Matic is shipped from the factory ready to install and function.

- There are no optional items required, and a complete installation kit is also included along with a comprehensive and detailed Owner’s Operation & Maintenance Manual.

- Worldwide Service and Sales Network for immediate attention regardless of location

- Technical service dedicated to excellent system performance

Specifications

Specifications

| Production | Model # | Per Hour | Per Day |

|---|---|---|---|

| 450-1 | 19 gal / 71 lit | 450 gal / 1,703 lit | |

| 700-1 | 29 gal / 110 lit | 700 gal / 2,650 lit | |

| 900-1 | 38 gal / 142 lit | 900 gal / 3,407 lit | |

| 900-2 | 38 gal / 142 lit | 900 gal / 3,407 lit | |

| 1400-2 | 58 gal / 221 lit | 1400 gal / 5,300 lit | |

| 1800-2 | 75 gal / 284 lit | 1800 gal / 6,814 lit |

| Weight | Model # | Compact | Modular |

|---|---|---|---|

| 450-1 | 153 lbs / 69 Kg | 149 lbs / 68 Kg | |

| 700-1 | 156 lbs / 71 Kg | 152 lbs / 69 Kg | |

| 900-1 | 158 lbs / 72 Kg | 154 lbs / 70 Kg | |

| 900-2 | 165 lbs / 75 Kg | 161 lbs / 73 Kg | |

| 1400-2 | 171 lbs / 76 Kg | 167 lbs / 76 Kg | |

| 1800-2 | 176 lbs / 80 Kg | 172 lbs / 78 Kg |

| Feed Inlet: | 3/4″ FNPT Female National Pipe Thread |

| Brine Discharge: | 3/4″ FNPT Female National Pipe Thread |

| Product: | 3/8″ MNPT Male National Pipe Thread |

| Pump Type | Phase | Pump Motor | Voltage VAC | Hz | NOA (110 / 220) | SUC |

|---|---|---|---|---|---|---|

| Plunger | Single | HP / Booster | 110-115 / 220-230 | 50/60 | 30 / 15 | 90 / 45 |

| Radial Axial | Single | HP / Booster | 220-230 / 380-460 | 50/60 | 35 / 17.5 220 / 380 – 44 |

95 / 48 |

| Plunger | Single | HP / Booster | 220-230 / 380-460 | 50/60 | 11 / 5.5 | 30/15 |

| Radial Axial | Three | HP / Booster | 220-230 / 380-460 | 50/60 | 11 / 5.5 | 30/15 |

| Operating AC Voltage | Phase | Recommended circuit breaker | |

|---|---|---|---|

| Plunger Pump | 110-115 / 220-230 | Single | 40 Ampere / 20 Ampere |

| Radial Axial Pump | 110-115 / 220-230 | Single | 40 Ampere / 20 Ampere |

| Plunger Pump | 220 / 380 / 460 | Three | 15 Ampere / 10 Ampere / 10 Ampere |

| Radial Axial Pump | 220 / 380 / 460 | Three | 15 Ampere / 10 Ampere / 10 Ampere |

Dimensions

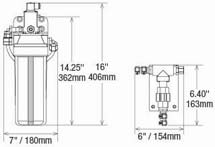

Accessories

Accessories

Touch Screen Remote Control

The user-friendly remote touch screen displays pictorial images of all operating conditions which can also be viewed from any location on the boat. All system readings can be selected to display either U.S. Standard or Metric measurements.

Fresh Water Flush

The fresh water flush greatly prolongs the life of the membranes by rinsing them with fresh water at the touch of a button. Automatically flushes your system every seven days.

Multi-Media Filter

The multi-media filter traps suspended solids larger than 30 microns to provide additional protection for the system’s pre-filters, which can greatly extend pre-filter element life.

Oil Water Separator

The Oil/Water Separator Canister protects the reverse osmosis membranes from oily or polluted water sources.

Commercial Pre filter

The Commercial size Pre-Filter Canister replaces the Standard Pre-Filters, providing longer intervals between necessary filter cleaning and replacement.

Plankton Filter

The plankton filter traps suspended solids larger than 100 micron, thus providing additional protection for the system’s pre-filters, which ultimately extend pre-filter element life (Dual design available).

pH Neutralizer

The Sea Recovery pH Neutralizing Filter provides pH neutralization of the reverse osmosis system product water.

Consumables

Consumables

Replacement Filters

Whether for the pre-filtration stage or post treatment stage, the Sea Recovery R.O. Filter Elements are an essential part in proper system performance.

Membrane Element Storage

These chemicals inhibit bacterial growth while maintaining the high flux and salt rejection of the R.O. Membrane Element.

Membrane Element Cleaning Compound #1 (SRC MCC-1) is an alkaline cleaner designed to clean biological fouling and slight oil fouling from the R.O. membrane element.

Membrane Element Cleaning Compound #2 (SRC MCC-2) is an acid cleaner designed to clean calcium carbonate and other mineral deposits from the R.O. membrane element.

Membrane Element Cleaning Compound #3 (SRC MCC-3) is used for iron fouling. If the system’s R.O. membrane element is fouled with rust from iron piping, then SRC CC-3 may be used for effective removal of light or moderate rust fouling.